|

NINGBO RUNNING BEARINGS CO.,LTD.

|

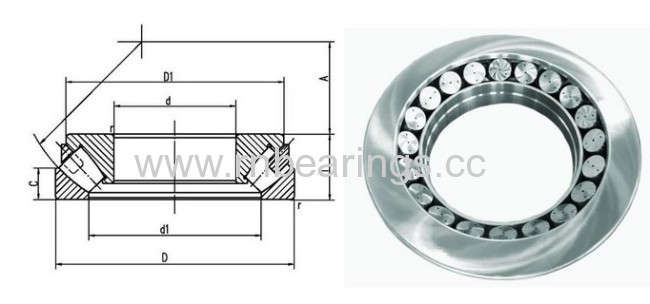

29440 E Spherical roller thrust bearings SKF Standard

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Spherical roller bearings 29440 E

Boundary Dimension: 200*400*122mm, Weight: 83.6kg.

Shape location tolerance should be to current standard.

Spherical roller thrust bearings 29440 E

Boundary Dimension: 200*400*122mm, Weight: 69.2kg.

In spherical roller thrust bearings the load is transmitted from one raceway to the other at an angle to the

bearing axis.

The bearings are therefore suitable to accommodate radial loads in addition to simultaneously acting axial

loads. Another important characteristic of spherical roller thrust bearings is their self-aligning

capability. This makes the bearings insensitive to shaft deflection and misalignment of the shaft relative

to the housing.

Spherical roller thrust bearings incorporate a large number of asymmetrical rollers and have specially

designed raceways with an optimum conformity. They can therefore support very heavy axial loads and permit

relatively high speed operation.

Spherical roller thrust bearings are produced in two designs depending on the size and series. Bearings up

to and including size 68 identified by the designation suffix E have a pressed steel window-type cage which,

with the rollers, forms a non-separable assembly with the shaft washer,

All spherical roller thrust bearings undergo a special heat treatment so that they can be operated at higher

temperatures for long periods, without the occurrence of inadmissible dimensional changes. For example, a

temperature of +200 °C for up to 2 500 h, or for shorter periods at even higher temperatures, is permitted.

All other bearings have a machined brass or steel cage which is guided by a sleeve held in the shaft washer

bore,The shaft washer and cage with rollers form a non-separable unit.

| Bearing No. | Basic Dimensions (mm) | Basic load ratings(kN) | Speed ratings(rpm) | Weight(kg) | ||||

| d | D | T | dyc(Cr) | stc(Cor) | Grease | Oil | ||

| 29412 | 60 | 130 | 42 | 275 | 425 | 1800 | 2600 | 2.48 |

| 29413 | 65 | 140 | 45 | 315 | 490 | 1700 | 2400 | 3.1 |

| 29414 | 70 | 150 | 48 | 438 | 1260 | 1700 | 2000 | 3.87 |

| 29415 | 75 | 160 | 51 | 440 | 700 | 1600 | 2200 | 4.59 |

| 29416 | 80 | 170 | 54 | 480 | 1600 | 1400 | 2000 | 5.43 |

| 29417 | 85 | 180 | 58 | 510 | 1650 | 1300 | 1900 | 6.57 |

| 29418 | 90 | 190 | 60 | 560 | 1980 | 1300 | 1800 | 7.66 |

| 29420/YA3 | 100 | 210 | 67 | 680 | 2000 | 850 | 1700 | 10.5 |

| 29320/YA3 | 100 | 170 | 42 | 340 | 1150 | 1450 | 2000 | 3.6 |

| 29322/YA3 | 110 | 190 | 48 | 440 | 1500 | 1350 | 1800 | 5.25 |

| 29422/YA3 | 110 | 230 | 73 | 840 | 2500 | 800 | 1500 | 13.3 |

| 29324/YA3 | 120 | 210 | 54 | 530 | 1750 | 1000 | 1600 | 6.88 |

| 29424 | 120 | 250 | 78 | 960 | 3000 | 750 | 1100 | 19.4 |

| 29424/YA3 | 120 | 250 | 78 | 960 | 3000 | 750 | 1100 | 19.5 |

| 29424J | 120 | 250 | 78 | 960 | 3000 | 750 | 1100 | 19.5 |

| 29426/YA3 | 130 | 270 | 85 | 1050 | 3500 | 700 | 1100 | 23 |

| 29326/YA3 | 130 | 225 | 58 | 610 | 2050 | 950 | 1500 | 8.26 |

| 29328/YA3 | 140 | 240 | 60 | 675 | 2150 | 880 | 1400 | 10.4 |

| 29428/YA3 | 140 | 280 | 85 | 1250 | 3850 | 670 | 950 | 22.7 |

| 29428J | 140 | 280 | 85 | 1250 | 3850 | 670 | 950 | 22.7 |

| 29330/YA3 | 150 | 250 | 60 | 750 | 2350 | 850 | 1400 | 10.8 |

| 29430/YA3 | 150 | 300 | 90 | 1280 | 4250 | 630 | 900 | 27.3 |

| 29332/YA3 | 160 | 270 | 67 | 850 | 2800 | 800 | 1300 | 14.3 |

| 29432/YA3 | 160 | 320 | 95 | 1500 | 5000 | 560 | 800 | 33.3 |

| 29334/YA3 | 170 | 280 | 67 | 880 | 2950 | 750 | 1200 | 14.8 |

| 29434/YA3 | 170 | 340 | 103 | 1650 | 5500 | 530 | 750 | 40.7 |

| 29336/YA3 | 180 | 300 | 73 | 1000 | 3400 | 720 | 1200 | 19.4 |

| 29436/YA3 | 180 | 360 | 109 | 1800 | 6000 | 515 | 750 | 42.3 |

| 29436J | 180 | 360 | 109 | 1800 | 6000 | 515 | 750 | 42.3 |

| 29338/YA3 | 190 | 320 | 78 | 1150 | 3850 | 680 | 1100 | 23.1 |

| 29438/YA3 | 190 | 380 | 115 | 2000 | 6500 | 500 | 735 | 60.1 |

| 29340/YA3 | 200 | 340 | 85 | 1280 | 4500 | 650 | 1050 | 28.5 |

| 29440/YA3 | 200 | 400 | 112 | 2200 | 7500 | 465 | 700 | 69.2 |

| 29244/YA3 | 220 | 300 | 48 | 484 | 910 | 750 | 1050 | 7.92 |

| 29348/YA3 | 240 | 380 | 85 | 1350 | 5200 | 600 | 920 | 35.5 |

| 29448/YA3 | 240 | 440 | 112 | 2400 | 8150 | 440 | 680 | 74.5 |

| 29252M/YA3 | 260 | 360 | 60 | 798 | 1550 | 530 | 750 | 15.7 |

| 29352 | 260 | 420 | 95 | 1700 | 6500 | 550 | 880 | 48.5 |

| 29452 | 260 | 480 | 132 | 2650 | 9850 | 400 | 650 | 105 |

| 29256 | 280 | 380 | 60 | 870 | 4000 | 500 | 700 | 19.1 |

| 29356 | 280 | 440 | 95 | 1800 | 7000 | 530 | 750 | 49.1 |

| 29260 | 300 | 420 | 73 | 1050 | 5050 | 450 | 650 | 30 |

| 29360 | 300 | 480 | 109 | 2050 | 8000 | 500 | 700 | 74.2 |

| 29264 | 320 | 440 | 73 | 1150 | 5600 | 420 | 600 | 32.5 |

| 29464 | 320 | 580 | 155 | 3500 | 13500 | 350 | 550 | 115 |

| 29268/YA3 | 340 | 460 | 73 | 1250 | 5800 | 400 | 600 | 31.4 |

| 29468 | 340 | 620 | 170 | 4000 | 15500 | 315 | 520 | 218 |

| 29372/YA3 | 360 | 560 | 122 | 2550 | 10000 | 350 | 550 | 107 |

| 29472 | 360 | 640 | 170 | 4300 | 16800 | 300 | 500 | 228 |

| 29280 | 400 | 540 | 85 | 1520 | 7750 | 375 | 500 | 55.1 |

| 29380 | 400 | 620 | 132 | 3200 | 12500 | 300 | 500 | 150 |

| 29480 | 400 | 710 | 185 | 5350 | 20150 | 275 | 465 | 306 |

| 29284/YA3 | 420 | 580 | 95 | 2060 | 10000 | 340 | 480 | 78.9 |

| 29488EM/YA3 | 440 | 780 | 206 | 6200 | 24800 | 250 | 400 | 407 |

| 292/500/YA3 | 500 | 670 | 103 | 2500 | 11500 | 300 | 450 | 100 |

| 294/500 | 500 | 870 | 224 | 6930 | 27700 | 230 | 340 | 462 |

| 292/530 | 530 | 710 | 109 | 2720 | 14000 | 275 | 420 | 122 |

| 292/560 | 560 | 750 | 115 | 3100 | 16600 | 250 | 380 | 131 |

| 294/560 | 560 | 980 | 250 | 11400 | 47800 | 200 | 220 | 750 |

| 294/600 | 600 | 1030 | 258 | 9500 | 40500 | 200 | 250 | 896 |

| 292/630YA3 | 630 | 850 | 132 | 3880 | 20250 | 220 | 300 | 231 |

| 294/670 | 670 | 1150 | 290 | 11000 | 54500 | 150 | 180 | 1214 |

| 292/710/YA3 | 710 | 950 | 145 | 4060 | 22500 | 180 | 240 | 279 |

| 294/750YA3 | 750 | 1280 | 315 | 14850 | 63500 | 100 | 120 | 1340 |

Spherical roller thrust bearings 29440 E