|

NINGBO RUNNING BEARINGS CO.,LTD.

|

Gold Index: 198811

You are here: home > Deep Groove Ball Bearing > Single row deep groove ball bearing > Deep groove Ball bearings single row

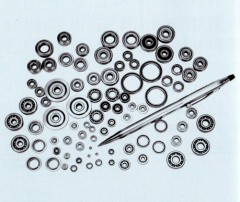

Deep groove Ball bearings single row

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

6001-2RS

Production Capacity:

500000 Piece/Pieces per Mon...

Delivery Date:

30 days

Structure:

Deep Groove

Number of Row:

Single Row

Material of ball:

Chrome steel

Means of Transport:

Ocean,Air

Packing:

RNB OR NATURAL

Brand Name:

RNB OR NATURAL

Type:

ball

Material of race:

Chrome steel

Precision:

P6

Deep groove ball bearing

It can sustain radial and axial loads and the resultant forces of these loads and they are suitable for high speed operation

Deep groove ball bearings

1) Structure andCharacteristics

A widely used bearing, the deep groove ball bearing takes its name from the formed on both the inner and ourer rings of thebearing. The bearings can sustain radial and axial loads and the resultantforces of these loads and they are suitable for high speedoperation.

The dimensional table below represents thevarious cage models and specialshapes.Drawing A is the pressed cage;drawing Bshows the machined cage;drawingsC through F show the position and shape of thenotch on the inner ring;anddrawing G shows a bearing with the key groove on themachined cages are used forlarger sized bearings, or bearings for high speedrotation.

1) Structure andCharacteristics

A widely used bearing, the deep groove ball bearing takes its name from the formed on both the inner and ourer rings of thebearing. The bearings can sustain radial and axial loads and the resultantforces of these loads and they are suitable for high speedoperation.

The dimensional table below represents thevarious cage models and specialshapes.Drawing A is the pressed cage;drawing Bshows the machined cage;drawingsC through F show the position and shape of thenotch on the inner ring;anddrawing G shows a bearing with the key groove on themachined cages are used forlarger sized bearings, or bearings for high speedrotation.

Except open bearings,most bearings manufactured by our company have shieldsorseals installed in both sides and are packed with a lubricant.Such bearingscansimplify the structure around them and also their installation. Italsoeliminates the needs for relubricaton. Therefore, it reducesmaintenancecost.

Deep groove ballbearings

Except open bearings,most bearingsmanufactured by ourcompany have shields or seals installed in both sides andare packed with alubricant.Such bearings can simplify the structure around themand also theirinstallation. It also eliminates the needs for relubricaton.Therefore, itreduces maintenance cost.

2) Materials for rings and rolling elements

While the contact surfaces between the bearing rings and rolling elements are subjected to repeated heavy stress, they must still maintain high rotational precission, therefore, the materials used for bearings rings and rolling elements require the following characteristics:

●High rolling contact fatigue strength

●High hardness

●High wear resistance

●High dimensional stability

●High mechanical strength

The material used by our company is high carbon chromium bearings steel GCr15-GB/T18254 equivalent such as AISI 52100(USA), DIN 100Cr6(Germany) JIS SUJ2(Japan) and BS 534A99 (UK).

Deep groove ball bearings

Deep groove ballbearings

Except open bearings,most bearingsmanufactured by ourcompany have shields or seals installed in both sides andare packed with alubricant.Such bearings can simplify the structure around themand also theirinstallation. It also eliminates the needs for relubricaton.Therefore, itreduces maintenance cost.

2) Materials for rings and rolling elements

While the contact surfaces between the bearing rings and rolling elements are subjected to repeated heavy stress, they must still maintain high rotational precission, therefore, the materials used for bearings rings and rolling elements require the following characteristics:

●High rolling contact fatigue strength

●High hardness

●High wear resistance

●High dimensional stability

●High mechanical strength

The material used by our company is high carbon chromium bearings steel GCr15-GB/T18254 equivalent such as AISI 52100(USA), DIN 100Cr6(Germany) JIS SUJ2(Japan) and BS 534A99 (UK).

Deep groove ball bearings

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Deep Groove Bearings

Deep Groove Ball Bearing

Deep Groove Ball

Groove Ball Bearings

Miniature Deep Groove Ball Bearing

Single Row Cylindrical Roller Bearings

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

NINGBO RUNNING BEARINGS CO.,LTD. [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

You May Like:

Product (2628)

- Automobile Bearings (21)

-

Ceramic Bearing

(151)

- Stainless Steel Bearing (130)

- Deep Groove Ball Bearing (174)

- Cylindrical Roller Bearing (271)

- Needle Roller Bearing (671)

- Tapered Roller Bearing (658)

- Spherical Roller Bearing (352)

- Thrust Ball Bearing (43)

- Tapered Roller Thrust Bearing (25)

- Spherical Roller Thrust Bearing (63)

- Slewing Bearing (4)

- Linear bearing (29)

- Rolling element (34)

- Auto Water Pump Bearings (1)

- Others (1)