|

NINGBO RUNNING BEARINGS CO.,LTD.

|

Gold Index: 198811

You are here: home > Deep Groove Ball Bearing > Single row deep groove ball bearing > Deep groove ball bearing single bearing

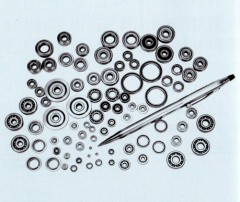

Deep groove ball bearing single bearing

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

6012-ZZ

Production Capacity:

500000 Piece/Pieces per Mon...

Delivery Date:

30 days

Structure:

Deep Groove

Number of Row:

Single Row

Material of ball:

Chrome steel

Means of Transport:

Ocean,Air

Packing:

RNB OR NATURAL

Brand Name:

RNB OR NATURAL

Type:

ball bearing

Material of race:

Chrome steel

Precision:

P6

Deep groove ball bearings

●High rolling contact fatigue strength

●High hardness

●High wear resistance

●High dimension alstability

Deep groove ball bearings

1)Materials for rings and rolling elements

While the contact surfaces between the bearing rings and rolling elements aresubjected torepeated heavy stress,they must still maintain high rotationalprecission,therefore, the materials used for bearings rings and rolling elementsrequire the following characteristics:

●High rolling contact fatigue strength

●High hardness

●High wear resistance

●High dimension alstability

●High mechanical strength

The material used by our company is high carbon chromium bearings steelGCr15-GB/T18254 equivalent such as AISI 52100(USA), DIN100Cr6(Germany)JISSUJ2(Japan) and BS534A99(UK).

2)Materials for cages

The materials for cages must have strength towith stand rotation at load andshock load. Low frictional efficiency light weight and be able to with stand operation temperature.

The material used in rib boncagesor crown cages is 08F or SPCC pressed.

It is chemical composition is shown for extra-high speed application. Plastic cages such as glass reinforced poly mideareused.

These plastic crown have the advantages of low torque,long grease lefe and lownoise, etc.

3)Vibration and noise

●The measuring parameter of vibration adopted by RNB is the vibration acceleration of vibration velocity.

● The measuring units and measuring method arespecified by JB/T5314 and JB/T5313 In the process of measuring vibrationstrictly controlled noise by using acoustics.

Deep groove ball bearings

1)Materials for rings and rolling elements

While the contact surfaces between the bearing rings and rolling elements aresubjected torepeated heavy stress,they must still maintain high rotationalprecission,therefore, the materials used for bearings rings and rolling elementsrequire the following characteristics:

●High rolling contact fatigue strength

●High hardness

●High wear resistance

●High dimension alstability

●High mechanical strength

The material used by our company is high carbon chromium bearings steelGCr15-GB/T18254 equivalent such as AISI 52100(USA), DIN100Cr6(Germany)JISSUJ2(Japan) and BS534A99(UK).

2)Materials for cages

The materials for cages must have strength towith stand rotation at load andshock load. Low frictional efficiency light weight and be able to with stand operation temperature.

The material used in rib boncagesor crown cages is 08F or SPCC pressed.

It is chemical composition is shown for extra-high speed application. Plastic cages such as glass reinforced poly mideareused.

These plastic crown have the advantages of low torque,long grease lefe and lownoise, etc.

3)Vibration and noise

●The measuring parameter of vibration adopted by RNB is the vibration acceleration of vibration velocity.

● The measuring units and measuring method arespecified by JB/T5314 and JB/T5313 In the process of measuring vibrationstrictly controlled noise by using acoustics.

Deep groove ball bearings

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Deep Groove Ball Bearing

Miniature Deep Groove Ball Bearing

Deep Groove Bearing

Nsk Groove Ball Bearing

Fag Groove Ball Bearing

Single Row Ball Bearing

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

NINGBO RUNNING BEARINGS CO.,LTD. [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

You May Like:

Product (2628)

- Automobile Bearings (21)

-

Ceramic Bearing

(151)

- Stainless Steel Bearing (130)

- Deep Groove Ball Bearing (174)

- Cylindrical Roller Bearing (271)

- Needle Roller Bearing (671)

- Tapered Roller Bearing (658)

- Spherical Roller Bearing (352)

- Thrust Ball Bearing (43)

- Tapered Roller Thrust Bearing (25)

- Spherical Roller Thrust Bearing (63)

- Slewing Bearing (4)

- Linear bearing (29)

- Rolling element (34)

- Auto Water Pump Bearings (1)

- Others (1)