|

NINGBO RUNNING BEARINGS CO.,LTD.

|

Gold Index: 198811

You are here: home > Deep Groove Ball Bearing > Single row deep groove ball bearing > Deep groove ball bearing single bearing with press cage

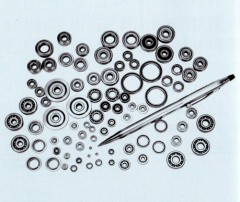

Deep groove ball bearing single bearing with press cage

| Payment Terms: | T/T,L/C,WU |

| Place of Origin: | Zhejiang, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Model No.:

6305-2RS

Production Capacity:

500000 Piece/Pieces per Mon...

Delivery Date:

30 days

Structure:

Deep Groove

Number of Row:

Single Row

Material of ball:

Chrome steel

Means of Transport:

Ocean,Air

Packing:

RNB OR NATURAL

Brand Name:

RNB OR NATURAL

Type:

ball bearing

Material of race:

Chrome steel

Precision:

P0

Deep groove ball bearings

P5tolerances for bearings up to a 52mmoutsidediameter

P6 tolerances forbearings above 52 mm up to 110 mm outside diameter

Deep groove ball bearings

1)Materials for rings and rolling elements

While the contact surfaces between the bearing rings and rolling elements are subjected torepeated heavystress,theymust still maintainhigh rotational precission,therefore, thematerials used for bearings rings and rolling elements require the following characteristics:

●High rolling contact fatigue strength

●High hardness

●High wear resistance

●High dimensional stability

●High mechanical strength

The material used by ourcompanyis high carbonchromium bearings steel GCr15-GB/T18254 equivalent such as AISI52100(USA),DIN100Cr6(Germany) JISSUJ2(Japan)andBS534A99(UK).

2)Materialsfor cages

The materials for cages must have strength towith standrotation at load and shock load. Low frictional efficiency light weight andbe able to with stand operation temperature.

The material used in ribbonc ages or crown cages is08F orSPCC pressed.

It is chemical compositionis shown for extra-high speed application. Plastic cages such as glassre in forced polymide are used.

These plastic crown have the advantages of low torque,long grease lefe and low noise,etc.

3)Vibration and noise

●The measuring parameter of vibration adopted by RNB is the vibration acceleration of vibration velocity.

● The measuring unitsandmeasuring method arespecified by JB/T5314 and JB/T5313 In the process of measuring vibrationstrictly controlled noise by using acoustics.

4)Internal clearance

Single row deep groove ball bearings are manufactured with Normal radial internal clearanceas standard. Most of the bearings are also available with C3 radial internal clearance. Some of the bearings can also besupplied with as maller C2 clearanceor the much greater C4 or C5 clearances. Inaddition, deep groove ballbearingsare available with reduced or displacedinternal clearance ranges. These special clearances may use reduced ranges of standard clearance classes orpartitions of adjacent classes, see designation suffix CN in section.

5)Tolerances

Singlerowdeepgroove ball bearings are manufactured asstandardtonormaltolerances.

Single row deep grooveballbearingsare produced to higher precision than the ISONormaltolerances. Thedimensional accuracy corresponds to P6 tolerances, expect the width tolerance,which is consider ably tighter andreduced to

-0/–60μm for bearings with outside diameter up to 110 mm

-0/–100μm for larger bearings.

The running accuracy depend on the bearing size and corresponds to

- P5 tolerances for bearings up to a52mm outside diameter

- P6 tolerances forbearings above 52 mm up to 110 mm outside diameter

- Normal tolerances for larger bearings.

For bearing arrangements where accuracy is a key operational factor, some SKF single row deep groove ball bearings are alsoavailable with accuracy completely to P6 orP5tolerance classs pecifications.The availability of these bearings should always be checked before ordering.

Deep groove ballbearings

1)Materials for rings and rolling elements

While the contact surfaces between the bearing rings and rolling elements are subjected torepeated heavystress,theymust still maintainhigh rotational precission,therefore, thematerials used for bearings rings and rolling elements require the following characteristics:

●High rolling contact fatigue strength

●High hardness

●High wear resistance

●High dimensional stability

●High mechanical strength

The material used by ourcompanyis high carbonchromium bearings steel GCr15-GB/T18254 equivalent such as AISI52100(USA),DIN100Cr6(Germany) JISSUJ2(Japan)andBS534A99(UK).

2)Materialsfor cages

The materials for cages must have strength towith standrotation at load and shock load. Low frictional efficiency light weight andbe able to with stand operation temperature.

The material used in ribbonc ages or crown cages is08F orSPCC pressed.

It is chemical compositionis shown for extra-high speed application. Plastic cages such as glassre in forced polymide are used.

These plastic crown have the advantages of low torque,long grease lefe and low noise,etc.

3)Vibration and noise

●The measuring parameter of vibration adopted by RNB is the vibration acceleration of vibration velocity.

● The measuring unitsandmeasuring method arespecified by JB/T5314 and JB/T5313 In the process of measuring vibrationstrictly controlled noise by using acoustics.

4)Internal clearance

Single row deep groove ball bearings are manufactured with Normal radial internal clearanceas standard. Most of the bearings are also available with C3 radial internal clearance. Some of the bearings can also besupplied with as maller C2 clearanceor the much greater C4 or C5 clearances. Inaddition, deep groove ballbearingsare available with reduced or displacedinternal clearance ranges. These special clearances may use reduced ranges of standard clearance classes orpartitions of adjacent classes, see designation suffix CN in section.

5)Tolerances

Singlerowdeepgroove ball bearings are manufactured asstandardtonormaltolerances.

Single row deep grooveballbearingsare produced to higher precision than the ISONormaltolerances. Thedimensional accuracy corresponds to P6 tolerances, expect the width tolerance,which is consider ably tighter andreduced to

-0/–60μm for bearings with outside diameter up to 110 mm

-0/–100μm for larger bearings.

The running accuracy depend on the bearing size and corresponds to

- P5 tolerances for bearings up to a52mm outside diameter

- P6 tolerances forbearings above 52 mm up to 110 mm outside diameter

- Normal tolerances for larger bearings.

For bearing arrangements where accuracy is a key operational factor, some SKF single row deep groove ball bearings are alsoavailable with accuracy completely to P6 orP5tolerance classs pecifications.The availability of these bearings should always be checked before ordering.

Deep groove ballbearings

Didn't find what you're looking for?

Post Buying Lead or contact

HiSupplier Customer Service Center

for help!

Related Search

Deep Groove Ball Bearing

Miniature Deep Groove Ball Bearing

Deep Groove Bearing

Nsk Groove Ball Bearing

Fag Groove Ball Bearing

Ball Bearing Cage

More>>

Find more related products in following catalogs on Hisupplier.com

Company Info

NINGBO RUNNING BEARINGS CO.,LTD. [China (Mainland)]

Business Type:Manufacturer, Trading Company

City: Ningbo

Province/State: Zhejiang

Country/Region: China (Mainland)

You May Like:

Product (2628)

- Automobile Bearings (21)

-

Ceramic Bearing

(151)

- Stainless Steel Bearing (130)

- Deep Groove Ball Bearing (174)

- Cylindrical Roller Bearing (271)

- Needle Roller Bearing (671)

- Tapered Roller Bearing (658)

- Spherical Roller Bearing (352)

- Thrust Ball Bearing (43)

- Tapered Roller Thrust Bearing (25)

- Spherical Roller Thrust Bearing (63)

- Slewing Bearing (4)

- Linear bearing (29)

- Rolling element (34)

- Auto Water Pump Bearings (1)

- Others (1)